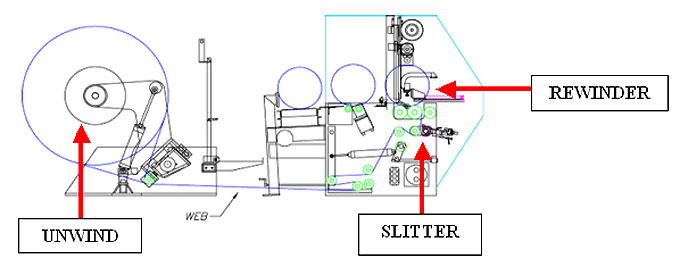

고속점보 롤 슬리터 리와인더

1. 이 슬리 터 Rewinder는 종이, 합성 재료, 알루미늄 호일, 인쇄 필름, PE, PP, PET, PVC를 슬릿 팅하는 데 적합합니다.

이러한 플라스틱 필름 등 그것은 이상적인 기계입니다

처리를위한 인쇄 포장 comparry.

2.Enlire 기계는 PLC (2 개의 벡터 모터), man-machine 인터페이스, screen louch 작동으로 conlock됩니다.

3.Unwind 부속은 수입 한 공압 브레이크 통제를 채택하고,

롤 지름은 PLC에 의해 자동으로 계산되며,

일정한 장력 조절을 달성한다.

4. Tracion 제어는 일정한 선 속도 제어를 달성하기 위해 veclor 가변 주파수 모터에 의해 구동되며,

그리고 되감기와 풀기 사이의 비 강제적 인 긴장을 효과적으로 차단합니다.

5. 되감기 샤프트는 벡터 주파수 모터에 의해 구동되는 점화를 사용합니다. 되감기 장력 조절은

되감기 지름, 두께, 장력 설정 등. PLC 출력 제어 신호에 의한 조작 후,

마찰 압력, 장력을 감는 목적을 달성하기 위해.

6.Unwind 부분은 많은 노동력과 시간을 절약 할 수있는 shaftless, 유압 전원 공급 장치를 채택한다.

7.Auto 미터 presetting, EPC 오류 수정 장치는 정확성을 보장하기 위해 긍정적이다.

기계의 8.The 특징은 안정성, 안전, efficienct, 등등이다.

제품 매개 변수

최대 웹 너비 1100-1800mm

최대 되감기 직경 500mm

최대 권취 직경 600-1000mm

최소 너비 20mm

절삭 정밀도 0.3mm

전원 전압 10KW

커팅 페이드 10-300m / min

전체 치수 (L * W * H) 2.2 * 2.6 * 1.5

기계 중량 3500kg

DaeHo Industry Company

High-speed jumbo roll slit reel winder

1. The slitter rewinder is suitable for slitting paper, synthetic material, aluminum foil, printing film, PE, PP, PET, PVC.

Such plastic film etc. It is an ideal machine

Printed packaging for processing comparry.

2.Enlire machine is conlocked with PLC (2 vector motors), man-machine interface, screen louch operation.

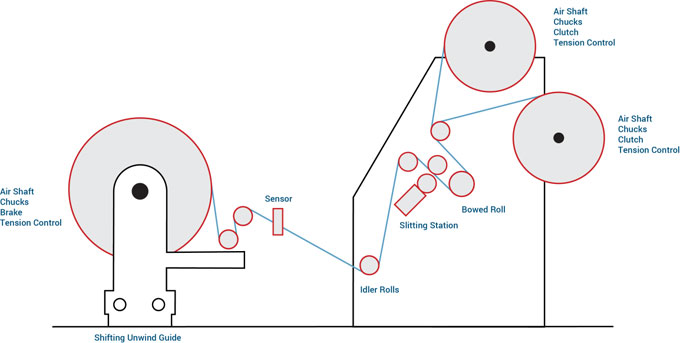

3.Unwind parts adopts imported pneumatic brake control,

The roll diameter is automatically calculated by the PLC,

Achieves constant tension control.

4. Tracion control is driven by a veclor variable frequency motor to achieve constant linear velocity control,

It effectively blocks non-coercive tension between rewinding and unwinding.

5. The rewinding shaft uses ignition driven by a vector frequency motor. Rewinding tension adjustment

Rewind diameter, thickness, tension setting, etc. After operation by PLC output control signal,

Friction pressure, to achieve the purpose of winding tension.

6.Unwind part adopts shaftless, hydraulic power supply which saves a lot of labor and time.

7.Auto meter presetting, EPC error correction device is positive to ensure accuracy.

8.The features of the machine are stability, safety, efficienct, and so on.

Product parameters

Maximum web width 1100-1800mm

Maximum rewind diameter 500mm

Maximum winding diameter 600-1000mm

Minimum width 20mm

Cutting accuracy 0.3 mm

Power supply voltage 10KW

Cutting fade 10-300m / min

Overall dimensions (L * W * H) 2.2 * 2.6 * 1.5

Machine weight 3500kg